• 24 volt DC drive rollers

• Saves power, time and money

• Zero pressure product accumulation

• Complete carton control and positioning

• Reduction of high voltage components

• Safe, quiet and low to no maintenance

Request a Quote

For all Quotes and orders please contact us:

Call Us: 616-540-9387

Email: info@jescoconveyors.com

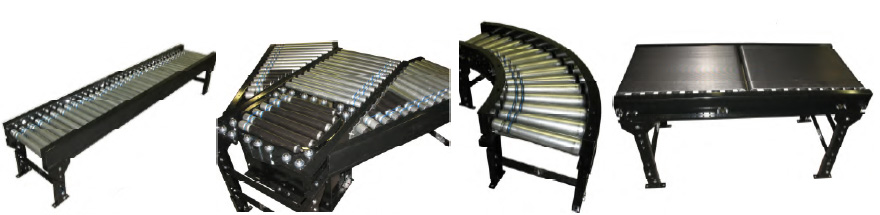

Beds: 16” ,20”, 24” and 30” widths between frame rails, 6 1/2” deep x 2” x 12 gauge powder coated formed steel, bolted together with butt couplings and floor supports.

Rollers: 16 gauge galvanized steel rollers, 1.9” dia with hex axle. Double groove rollers spaced on 2.5”,3” and 4” centers slave driven by polyurethane “O” rings. Rollers can be set low (2” below frame top) or high (1/4” above frame top).

Motorized Rollers: 24VDC drive rollers available in standard, high torque, or brake motors. Variable speeds and direction available. Rollers only run when product passes and remains “asleep” when not in use. Sensors: Reflective photo eyes available for rollers low application. Proximity photo eyes available for rollers high application.

Accumulation Zones: Zero pressure accumulation zones. Available in standard 18”, 24” and 30” lengths, and must be equally divisible by the center distance of rollers.

Power: A power supply unit is required to operate and control the driver cards.

Capacity: Depending on product type and speed, rollers can handle up to 100 lbs.

Floor Supports: Adjustable floor supports available to satisfy elevation needs. Conveyor Speed: Speed is determined upon the needs of the customer. Standard speed range is 35-175 FPM.

Side Covers: Available on all standard applications. Side covers offer protection of electrical components and a clean appearance.

Belted Zones: Used with incline and decline applications for increased traction.

Curves: 30, 45, 60 and 90 degrees.

Merges: Merges product onto a straight conveyor. Right Angle Transfer: An economical way of transferring product 90 degrees on and off the main conveyor line.

Spurs: Used with diverting application

Diverts: Diverts product onto separate conveyor at a 30 degree angle connected to a spur.

Electrical Controls: Plug and play system eliminates the need for expensive field wiring. Comes pre wired and programmed.